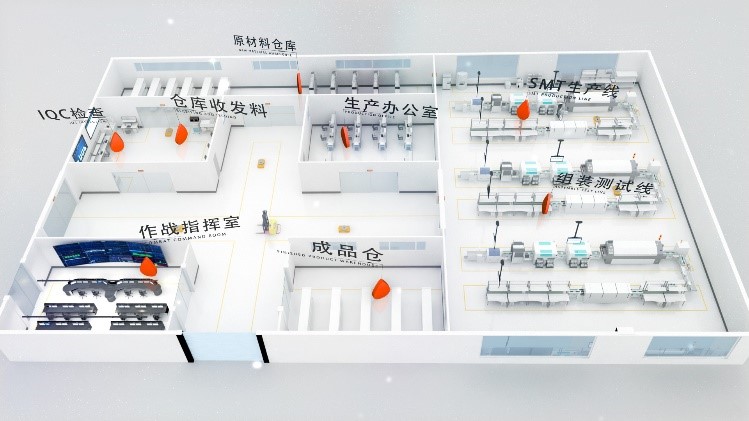

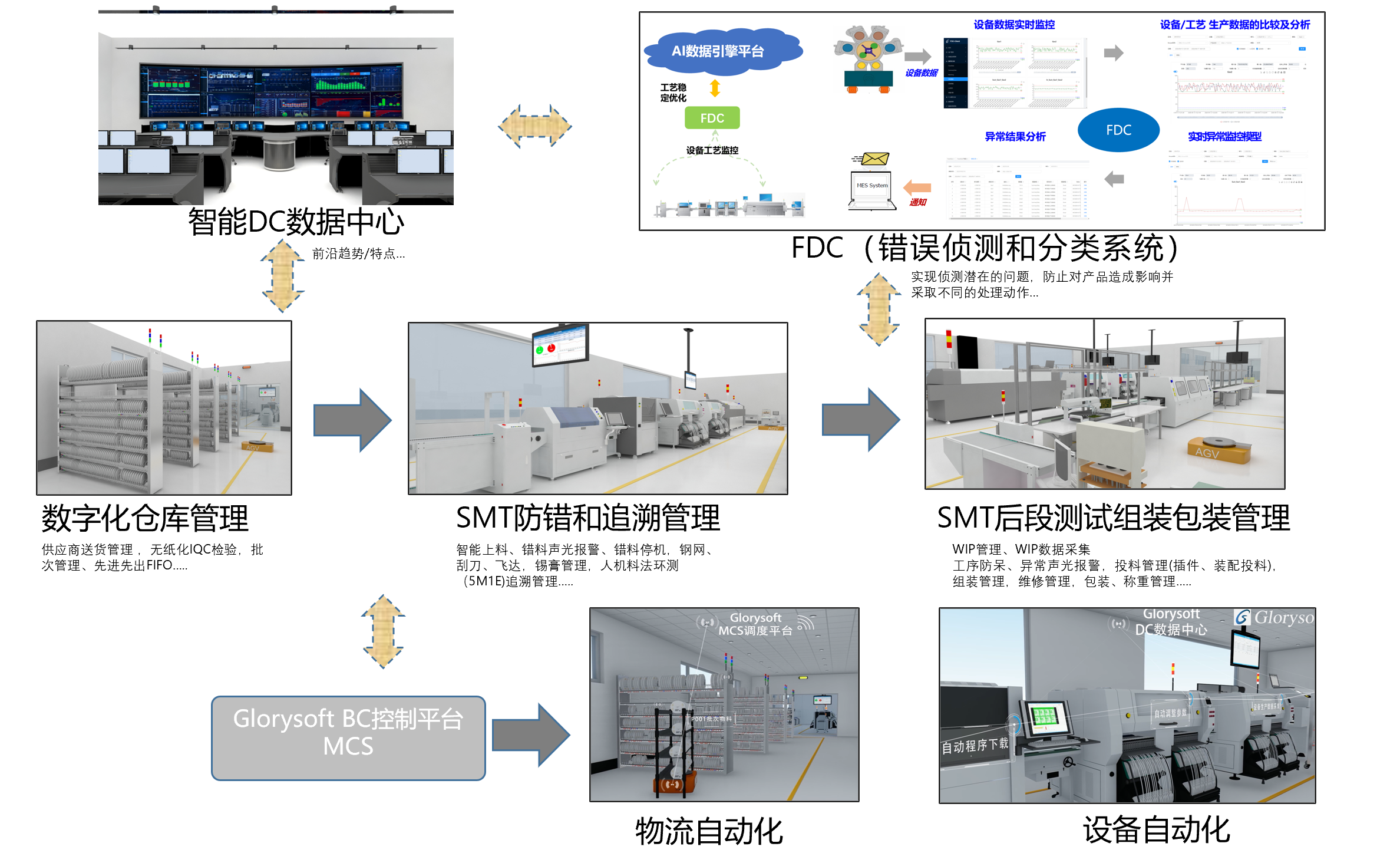

System adopts the advanced bar code technology and network communication technology, integrated with all kinds of automation equipment, electronic manufacturing process was optimized, from supplier, warehouse to SMT, assembly testing, packaging, quality management, such as the entire information management, and with the ERP system, such as seamless docking, a mistake proofing cues personnel, comprehensive, efficient operation, cut back

Glorysoft has made full use of the experience of intelligent production solutions in semiconductor and panel industries in recent years, and has joined hands with enterprises and experts in the field of PCBA to build an industry-leading intelligent manufacturing and big data AI application closed-loop system, and jointly build a benign intelligent enterprise ecosystem. Help manufacturing enterprises to set up plant planning, build digital information platform, automation deep transformation, continuous lean improvement, jointly realize the transformation of enterprise intelligence and wisdom, build enterprise competitive core force.

Understand the processing progress of production orders in real time ●

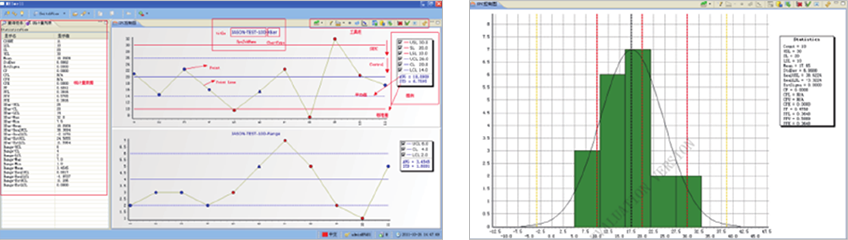

Real-time knowledge of production line output and yield, pass rate, defect distribution ●

Forward and reverse product traceability ●

5M1E (person, machine, material, method, ring, measurement) traceability●

● Process error prevention, personnel reduction

● Efficiency raised, abnormal alarm

● Based on big data, artificial intelligence and deep learning technologies

●Industrial Internet can be implemented in multiple scenarios