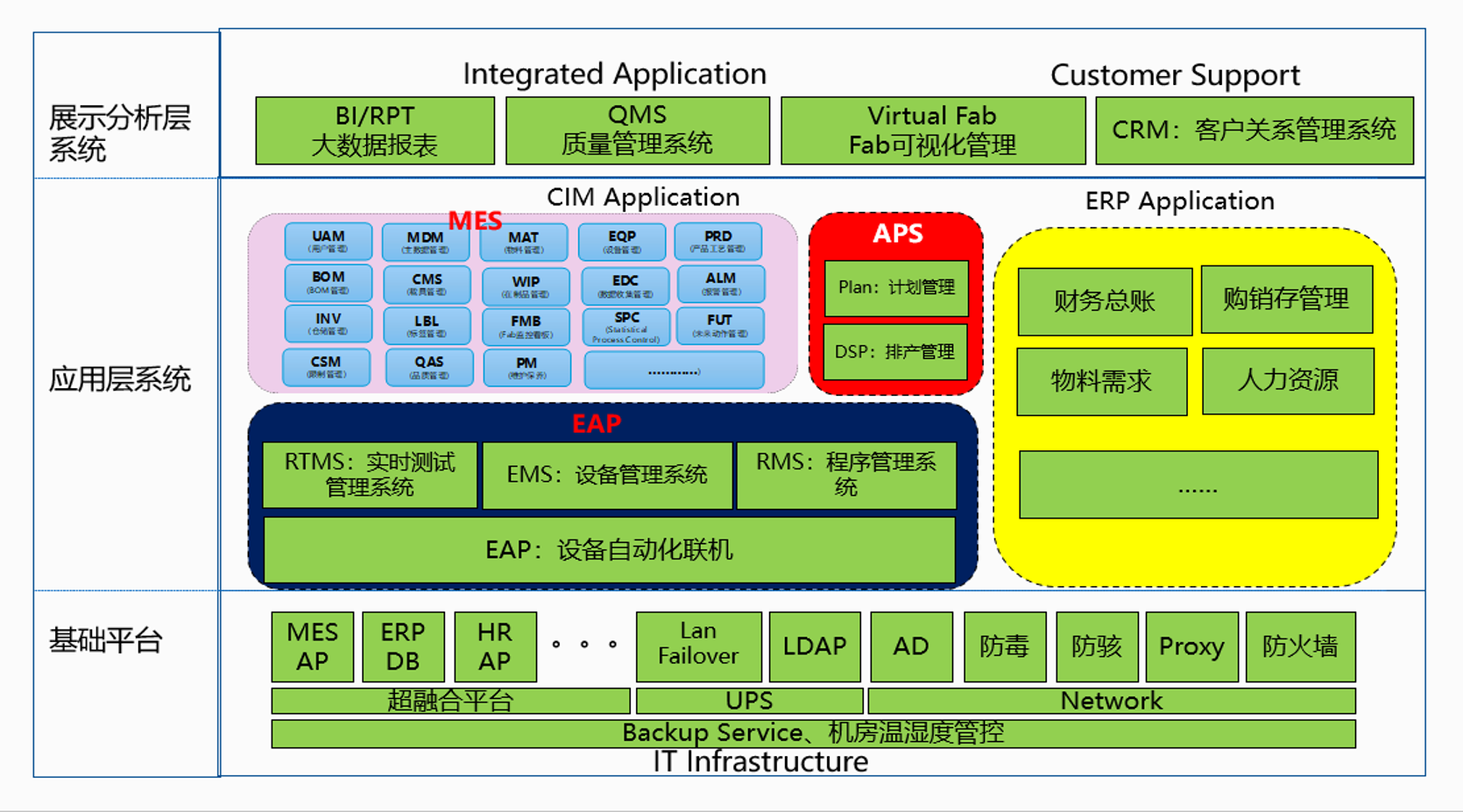

As a general contractor to implement ERP, CRM and OA product integration

As the general contractor to implement the basic platform and machine room scheme architecture

1) Modeling of packaging data, supporting interaction with Bartender label software; 2) Customizing labels according to customers and controlling the contents of the labels by order/product/customer; 3) automatically opening and displaying the packaging documents during repackaging; 4) Material tray packaging and pipe belt packaging; 5) Single signing and multi-signing mode of the end of the order; 6) Statement management and automatic statement; 7) Intelligent shelf management to realize automatic bin management; 8) Manage storage by box, and interact with ERP

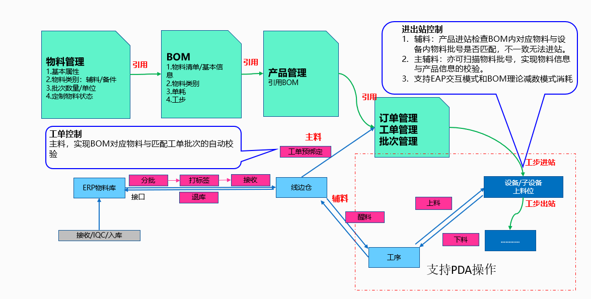

Interaction management with ERP, master data interaction management ●

The client is automatically upgraded●

Order management is integrated with APS ●

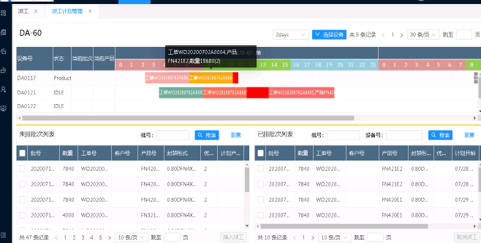

Monthly production capacity plan, production input plan, DB/WB/FT process production plan●

● Material and fixture management

● Develop management model for various raw materials and fixtures in packaging industry, and develop interface with ERP

● Realize the real - time consumption of materials and check the cost of work order

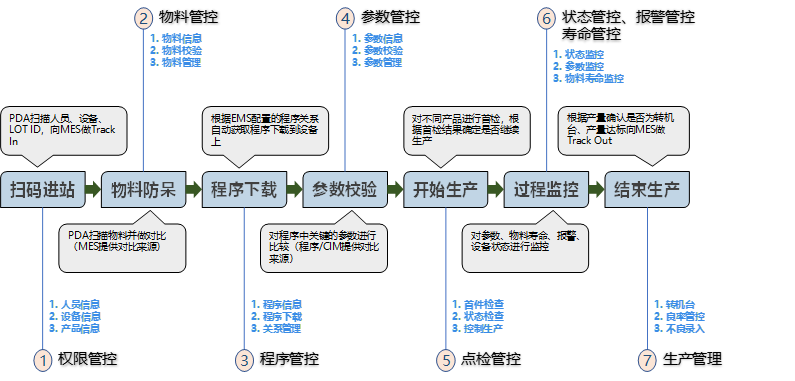

● CIM integration solution for assembly segment

● Through PDA integration, to achieve MES, EAP and other systems of interactive operations

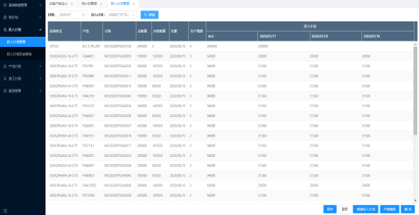

Master data synchronization: product information, material information, BOM information, and process information

Order management synchronization: normal order, rework order, disassembly order, change management

Material batch information synchronization: material information, consumption information

Synchronization of product warehousing information: Product warehousing

Monthly production capacity plan, production input plan, DB/WB/FT process production plan

Set up interface with ERP to realize real-time material consumption and check work order cost

To realize the interactive operation of MES, EAP and other systems

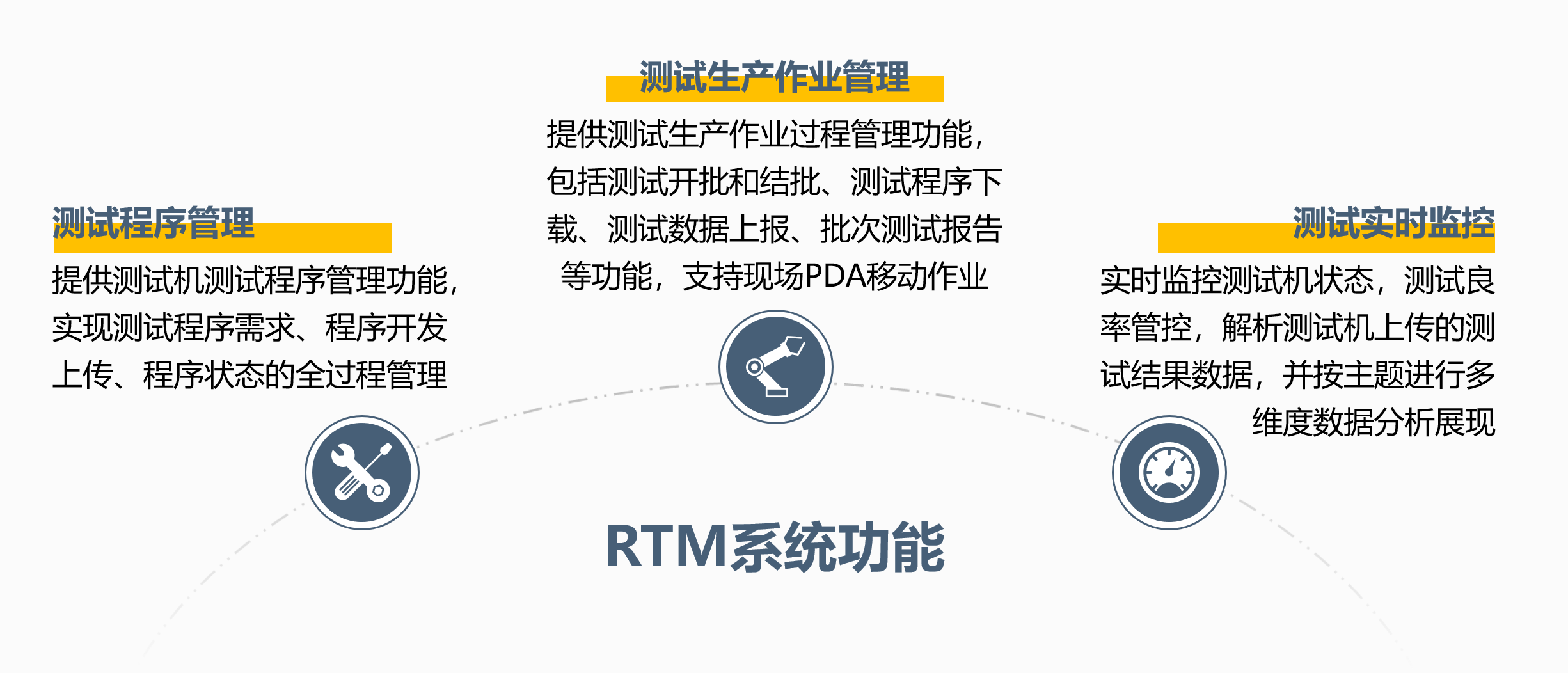

1) solve the mantissa order management disorder, 2) solve the FT test data integration, through the MES and sorting machine interaction, automatic obtaining product testing results, and realize the separator traceability of data and test machine data archive management, (3) automatic test program and the seal to be obtained, 4) automatically according to the packing base raw material management, 5) customer sample management, 6) Integration of internal testing and outsourced testing, 7) real-time control of low test performance, 8) first-piece inspection management