Guangzhou CICD was successfully held! Glorysoft iFDC escort semiconductor manufacturing!

From November 1-3, 2021, the 24th China IC Manufacturing Annual Conference and Supply Chain Innovation and Development Conference (CICD 2021) was successfully held in Guangzhou Huangpu Junlan Hotel! CICD is one of the most large-scale and influential seminars in the field of IC manufacturing in China. With the theme of "New Start, New Challenges, Vitality of Core, Vitality of Core", this conference covers the summit forum, special forum, exhibition and exchange, and more than 1,600 industry elites from the IC manufacturing industry chain attended the event.

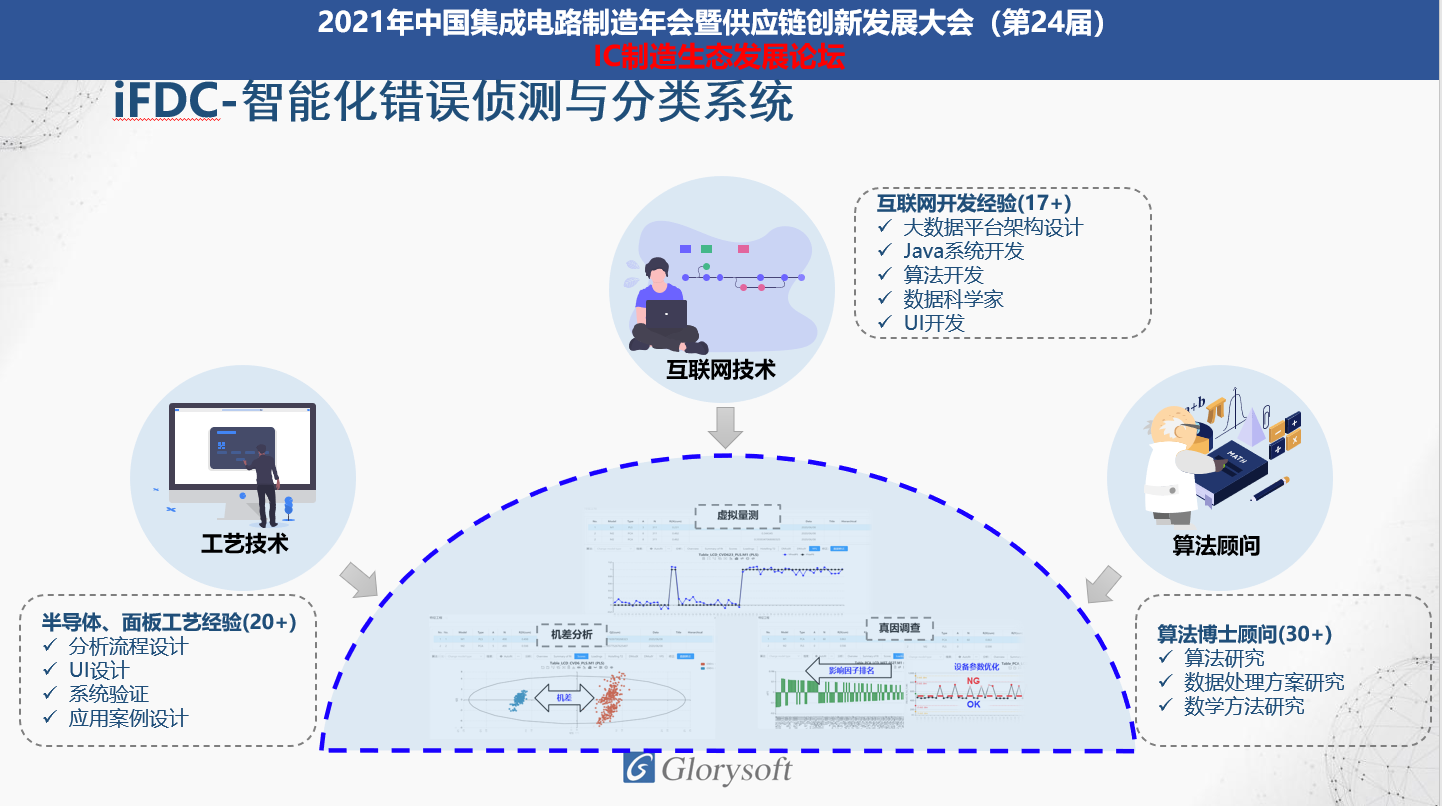

In the "IC Manufacturing Ecological Development Forum", Shi Weitang, Product Director of Shanghai Glorysoft Software Co., LTD., gave a keynote speech -- Data analysis application of intelligent error detection and classification system iFDC in semiconductor manufacturing. Let's have a look

What is iFDC

iFDC(Intelligent Fault Detection & Classification)system:

● Monitor production key indicator data in real time, quickly and accurately detect production problems.

● Real-time alarm notification of abnormal production status.

● Offline data analysis, quickly find the root cause of the problem, improve the efficiency of data analysis more than 10 times.

iFDC Application Cases

● Mechanical difference analysis

AI model analysis can quickly find the key impact parameters of machine differences, reducing the analysis time from the usual 4-6 hours to 10-30 minutes.

● Product difference analysis

AI model analysis can quickly find the key influencing parameters of product quality differences and improve the efficiency of finding Root Cause.

● Capacity analysis

AI model analysis can quickly find the key production units that affect the production capacity and provide analysis basis for improving the production capacity.

iFDC Future Outlook

● faster

Millisecond level data collection, huge amount of equipment docking and efficient data processing and fast analysis methods

● higher

Fault Detection beyond the Basics & Classification function to embrace big data analysis

● stronger

With the help of virtual function modeling and a variety of big data analysis algorithms, the data analysis function can be strengthened to enrich the expansion of application scenarios and liberate engineers' manpower

● More United

It provides rich data sources for other subsystems of the CIM system to jointly improve production capacity and yield for manufacturing